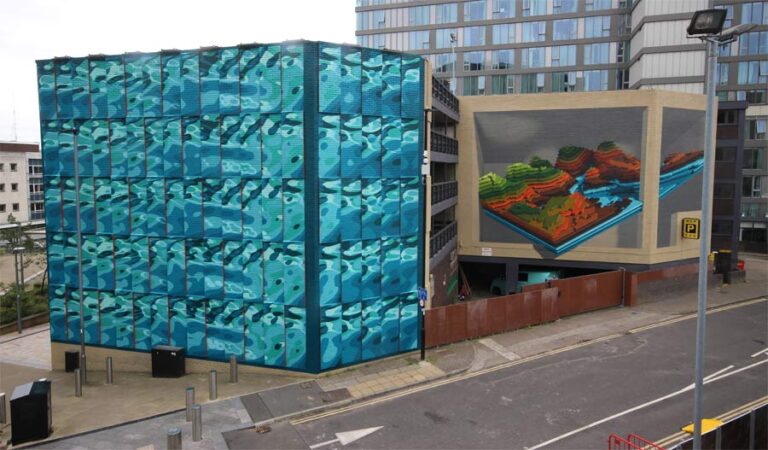

Innovative Road Construction in Blackpool Sets New Sustainability Benchmark

Road surfacing contractor Multipave has set a new benchmark for environmentally responsible road construction, using a combined solution that mixes recycled aggregates with Tarmac’s innovative surface course, as part of a groundbreaking 4,500m² carriageway reconstruction project for Blackpool Council.

At the heart of the project was 735 tonnes of Multipave’s Cold Recycled Bound Material (CRBM) produced at its aggregates recycling facility in Leyland. This material was created using waste planings from the existing carriageway, demonstrating a circular approach to road building.

To complete the surface layer, Tarmac supplied its Bio Ultiflex, a high-performance, low carbon surface course. This material, approved under Clause 942 BBA HAPAS certified, incorporates high PSV aggregates and a polymer-modified binder, ensuring long-term durability even under demanding traffic conditions.

The solution was deemed viable only after comprehensive investigation work to ensure that waste materials from the severely deformed carriageway could be reused.

Working collaboratively with Tarmac to find the right surface course, Multipave not only put forward an environmentally friendly recycled material, but also minimised transport movements too. Waste planings were backhauled on the same wagons delivering the CRBM to site, reducing transport movements to nearly half those typically associated with traditional base layer installation.

For Blackpool Council, and for other local authorities looking to reduce carbon emissions from their essential highways repair works, it proved the perfect solution for sustainable road surface replacement.

A combined solution

This is the second project on which Multipave has teamed up with longstanding partner Tarmac to deliver Bio Ultiflex in combination with their CRBM. On this scheme they utilised the latest generation of their CRBM which includes a biogenic additive that actively locks carbon into the material structure without compromising quality or performance.

By mixing at ambient temperatures, CRBM offers significant energy and carbon savings over traditional hot-mix asphalt. Multipave’s enhanced solution is made possible thanks to the use of Tarmac’s Bio Ultiflex, which is a thin surface course with outstanding long-term durability.

Total carbon emissions have been reduced by 34.9%, showcasing a significant step forward in sustainable infrastructure delivery. Furthermore, material production emissions (A1–A3) are 40% lower thanks to the combination of the Multipave CRBM binder course and Tarmac’s Bio-Ultiflex surface course. Emissions from material transport (A4) are also reduced by 62.4% through optimised logistics and integrated recycling operations.

Additionally, the combined solution reduced emission intensity per square metre by 35%, underlining its potential to drive meaningful carbon reduction across large-scale projects.

Stuart Bradshaw, Technical and Innovation Manager at Multipave said: “This project presented significant challenges, not least because of the condition of the existing carriageway, but we’re delighted to have developed a truly sustainable solution in every way.

“From the material itself that keeps waste materials in productive use, to the smart transport planning, we’ve delivered advancements in sustainability that help to set a new benchmark for environmentally responsible road maintenance.”

Gabrielle Fairweather, Aggregates and Asphalt Account Manager – North West and Yorkshire at Tarmac said: “Bio Ultiflex has been designed to deliver lasting performance in a variety of locations from rural roads to heavily trafficked motorways, and as Multipave has proved in its CRBM solution, this is the perfect surface course to support sustainability strategies.

“In fact, when used as a warm mix asphalt using Tarmac’s ULTILOW binder technology, it can help deliver up to 15% reduction in carbon dioxide emissions.

“More than that, Bio Ultiflex is only available for installation by accredited contractors who have full access to our expert training, advice and technical support, or by our own expert Contracting division. This ensures it is laid to the highest industry standards, and we’re delighted to have worked closely with Multipave once again on this pioneering project in Blackpool.”